Rapid Prototyping

Our rapid prototyping services use 3D printing, CNC machining, and custom fabrication to deliver functional parts in days. Whether you’re an inventor testing your first design or an engineering team validating performance, we create prototypes that help you move confidently toward production.

Our Process

1. Upload or Share Your Design – Send us a 3D file, drawing, or even a rough sketch. If you've already worked with us through the "Concept & Design" Phase, you can confidently move to the next stage:

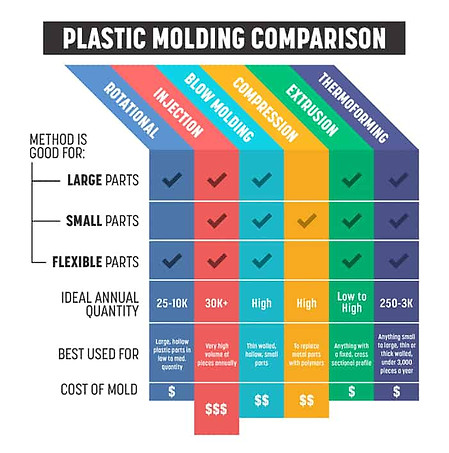

2. Material & Method Selection – We recommend the best process (3D printing, CNC, fabrication) based on part requirements. We are also experts in material translation based on the fabrication process. How well do dimensions translate from a 3D printed part to an injection molded part? With our team, you can rest easy knowing that your part will remain within tolerance throughout this process.

3. Prototype Fabrication – Build your prototype quickly with precision and attention to detail.

4. Review & Refine – Test, evaluate, and make adjustments before scaling to production.

01

Share your Design

We can sign a mutual NDA for your product idea prior to receiving your file. We can receive your file in any format. However, preferred file formats are .STEP, .F3D, .sldprt. If you have any file that is not in this format, please let us know and we will accommodate accordingly.

02

Material & Method Selection

Are your tolerances +/-0.0005?

Does this product need significant heat, UV, impact, etc. resistance?

Does it need to be biocompatible?

Do you need a conductive polymer for electroplating?

Thankfully, there is a fabrication process/material in the prototyping space that closely mimics the final production part.

Preparing the prototype with the end process in mind can save hundreds of design hours, because every material behaves uniquely within the fabrication process.

03

Prototype Fabrication

Prototype fabrication isn’t just about creating a physical part — it’s about ensuring every detail is aligned with the realities of final production. In the image provided, this was a deployed prototype (one of 220 models fabricated with 3D printed 95A TPU) that was sold in early market testing for our client, Vaucluse Gear.

We synchronize fabrication with manufacturing requirements, tolerances, material specifications, and assembly methods, so your prototype doesn’t just meet basic aesthetic and functional requirements — it performs as it will in full production.

This approach allows you to validate fit, function, and durability while avoiding costly redesigns later. Whether you need a one-off prototype, a small batch of test parts, or pre-production assemblies, our process bridges the gap between design and manufacturing, helping you move confidently from concept to scaled production.

04

Review and Refine

The Review and Refine stage is where your prototype is "put through the kiln" and transforms into a production-ready solution.

This stage is critical for reducing errors and avoiding costly delays once you move into low-volume manufacturing or full-scale production. Whether it’s adjusting dimensions, refining geometry, or improving material selection, our team works closely with you to align every change with the final manufacturing process. The result is a refined prototype that’s not only functional, but also optimized for rapid prototyping, small batch runs, and scalable manufacturing.